Creating a water filter from wood

1.1 billion people in the world don’t have access to safe drinking water. In fact, even though it’s 2014, we still have 1.6 million people dying from infections caused by the lack of safe drinking water and basic sanitation – 9 out of 10 of these are children under the age of 5.

For several years Rohit Karnik, a mechanical engineer at MIT, had been working on the development of membranes for water filtration. But during a conference in Israel, listening to someone talking about fluid motion in trees, inspiration struck.

*

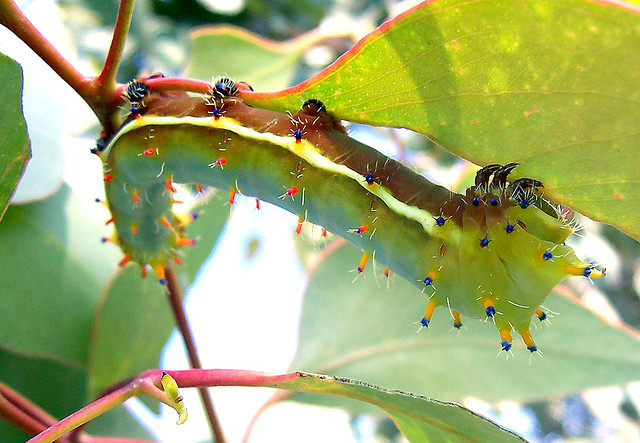

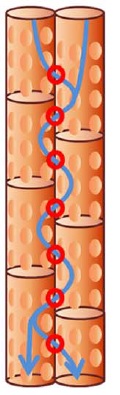

Apart from water, of course, trees transport so called “sap”, a fluid enriched with nutrients, up and down their trunks. On it’s way through the xylem, the wooden part of the tree, either fluid gets filtered at many points (circled in red). Now, why not investigate if these tree-membranes are capable of filtering water for humans as well? No sooner thought than done.

Karnik and his team started out developing a very minimalistic, low-cost filter – the problem with existing filters is often that they either need energy or are not affordable for those in need. So, Karnik’s first filters were built by peeling off the bark and plugging the piece of wood into a tube. Not suitable on a large scale, but elaborate enough for testing filter properties.

Construction of water filter system using wood*

The team’ s results: These filters got 99,9 percent of pathogens out of the water. The xylem filters managed to eliminate Escherichia coli, the most common type of gut bacteria that can cause severe diarrheal diseases if present in contaminated water.

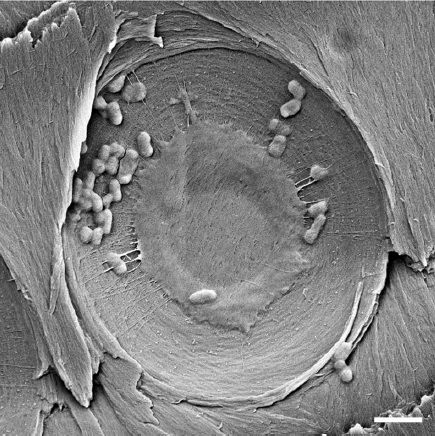

Using advanced microscope technology, the scientists even traced down, where bacteria where filtered: they all accumulated on the so called pits – membranes permeable for water – but not for the “larger” bacteria. Talking about size: the E. coli bacteria can be anything from 2 to 6µm in length. This is already quite small, but not the end of it when it comes to pathogens: viruses are almost a thousand times smaller than this. That is also where the xylem filters surrender: they don’t present an obstacle to anything smaller than 20 nm – a size comparable to that of the smallest viruses, the scientists report.

Pit membrane with accumulated E. coli bacteria. Scale bar: 2µm.*

To achieve a decent flow rate of 4 litres per day, researchers applied a pressure of 5 psi: “This value approximately corresponds to the pressure at the bottom of a 3 m column of water. Filtration will also occur at lower pressures, but at proportionally lower flow rates,” Karnik says. “The pressure of water supplied to households is typically 10 times this value. A container placed a few feet above the ground with a hose coming down to ground level will be able to generate sufficient pressure for filtration.”

Questions to be solved

Having this problem solved, there are still several left. “Can we store or dry sapwood xylem filters?” is one of the questions Karnik and his team are currently investigating. So far, to perform properly, filters have to stay wet all the time – once they’ve dried, they are useless. To safely get rid of such unusable or already “overused” filters, one way would be to burn them.

Also crucial for success of this filtration method is the type of wood used. For their experiments the team used the Eastern White Pine Pinus strobus, a tree that is abundant mostly across North America but not in those regions most in need of feasible water filtration: “We used the tree because it is common here, and it was easy to access. There are so many species of plants, and the question as to which endemic plants are suitable for making xylem filters in a particular area is certainly worthy of investigation,” Karnik writes.

Low cost solution in two years

Karnik’s idea is not yet feasible on large scales but he is optimistic: “This is a very new technology with lot of work to be done. A filter could take various forms, but one that is especially appealing is a compact device that simply attaches to a faucet, with a replaceable xylem filter inside it. It may take 2-3 years to develop the first prototypes for larger scale use, but I believe that there will be many developments to follow.”

*Credits for all images: CC BY: Boutilier et al. 2014, PLoS One 2014, doi:10.1371/journal.pone.0089934.g001